Mainsailz have assessed and reported on thousands of projects over the last 35 years ranging from

basic school shade sail safety inspections through to multimillion dollar major claims involving large

high-profile projects that require the experience and expertise to correctly complete these types of

claim investigations.

Some of our recent projects include:

| Name | The 02 Arena |

| Location | London, UK |

| Type | Storm Damage |

| Client | Insurance |

Details:

Consulting as part of a team of insurance experts & forensic engineers assessing a major claim involving damage that occurred during Storm Eunice which destroyed several PTFE panels at the iconic 02 Arena in London. Scope included initial damage assessment & site inspection, causation report, design review, emergency make safe works, temporary PVC panel replacement advise, PTFE panel replacement scope of work, tender review, and component testing.

Current Status: In progress since February 2022. Ongoing.

| Name | PVC Fabric Failure Claim |

| Location | Queensland, Australia |

| Type | Investigation & Fabric Testing |

| Client | Insurance & Legal |

Details:

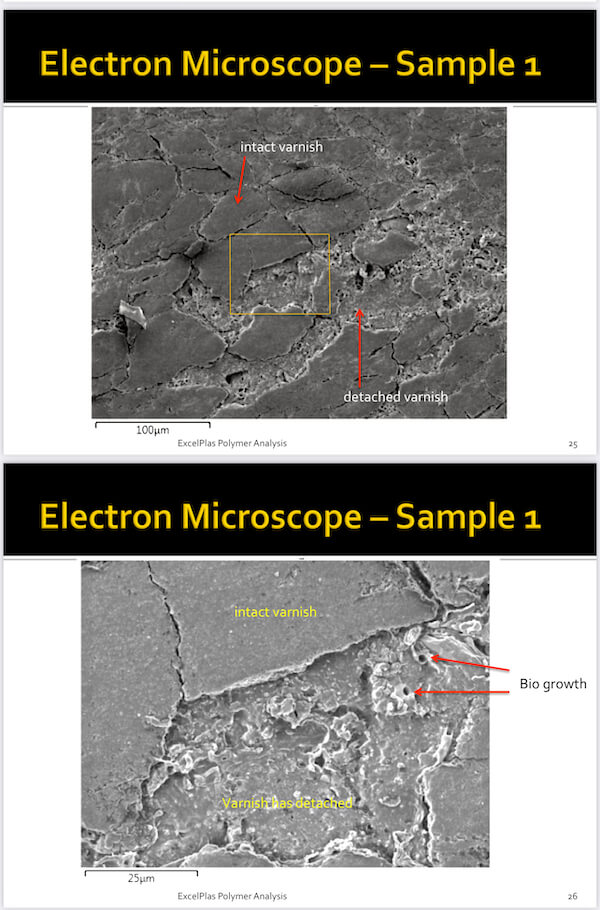

Investigation and causation report regarding the premature failure of multiple PVC fabric sail structures located at sites throughout Queensland. The sails were all manufactured from the same batch of a high-quality architectural grade PVC fabric and all experienced failures of their top surface PVDF coating. We reported to several parties regarding this matter including the fabric manufacture in France and their insurer, the asset owners and their respective legal teams , site engineers and fabric testing laboratories in France and Australia.

Current Status : Ongoing

| Name | Cyclone & Storm Damages Claims |

| Location | Queensland & NSW, Australia |

| Type | Insurance Assessment |

| Client | Loss Adjustor |

Details :

Local Government asset damage assessment : Assisting the insurance loss adjustors regarding storm and cyclone damage claims that occurred to numerous sites in Queensland & NSW where damage to fabric structures occurred. Our scope in all these projects was to inspect the damage, compile a like for like scope of works and issue tenders, review tenders received, recommend contractors, and sign off on the finished projects.

Current Status: Completed

| Name | Kuwait University |

| Location | Kuwait |

| Type | Storm Damage | Fabric Structure Water Ponding Investigation |

| Client | Insurance |

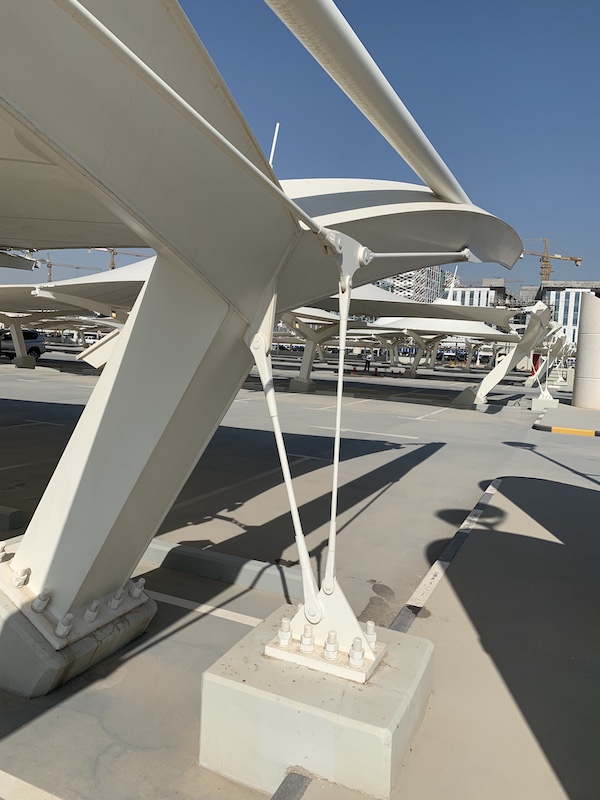

Details:

Investigation and report into the cause of a failure to several tensile fabric carpark structures located at a site owner by the Kuwait Government that occurred during a storm event. Our brief was to engage forensic engineers to review the design and visit the site to inspect the damage and discuss with all parties involved in the project and the cause of the failure.

Our scope included fabric testing, contract review, design review, water ponding modelling analyses, weather records review and writing a report that identified the cause of the failure.

Current Status: Completed

| Name | School Playground Safety Inspections |

| Location | Victoria, Australia |

| Type | Inspections & Reports |

| Client | Education |

Details:

Playground Shade Sail Safety & Engineering Inspections: Being one of the only shade sail inspection firms to hold the correct profession indemnity insurance required for these types of projects our team regularly undertakes inspections of school-based playground shade sails in Victoria using our specifically developed LiveGenic software technology. This allows us to produce a comprehensive report that checks all elements of the shade structure and includes engineering analysis if required.

These type inspections are required for all Victorian Schools to comply with Worksafe Victoria guidelines, and our detailed reports are designed to meet all these requirements.

Current Status : Ongoing since 2016

| Name | Golf Driving Range | Failure of Sail Structure | Water Ponding |

| Location | Brisbane, Australia |

| Type | Investigation & Report |

| Client | Insurance Loss Adjustor |

Details :

Investigation into the failure of a waterproof sail and frame located above a driving range at a golf club that had pooled with water and collapsed during a rain event. The damaged caused was subject to an insurance claim. We were required to inspect the site , review the original engineering drawings and check the as built design to compare with the design specifications. These including footings , steel member sizes and fabric specifications with fabric samples from site being sent to Germany for tensile testing and identification.

We were assisted by a forensic engineer with expertise in tensile fabric structures who was able to create a model of the design to check for engineering and building code compliance. Our investigation found that the combination of faulty engineering design specifications and incorrect installation that included the use of a PVC fabric that was not specified had contributed to the failure.

Current Status: Completed

| Name | Shade Sail Safety Inspections |

| Location | Melbourne, Victoria |

| Type | Inspection & Reports |

| Client | Local Government |

Details:

We recently undertook a detailed safety inspection and report of playground shade sails at over 60 sites owned by a Victorian Council including footing , post and sail inspections. Our scope was to inspect each site to identify any damage, check engineering and OHS compliance and recommend any repairs or replacements required.

We were able to identify several urgent maintenance issues that required immediate rectification and report of the expected lifespan of the structures including an asset management plan.

Current Status: Completed

| Name | Carpark Sail Structures Damage |

| Location | Queensland & NSW |

| Type | Investigation & Report |

| Client | Insurance |

Details:

Consulting with the insurer of several shopping centres with regards to damage that was occurring to framed car park structures at various locations that were being hit by high clearance vehicles on a regular basis.

Our scope was to firstly issue a tender request several contractors to repair the damaged and approve the successful tender, then report on the options available to reduce the risk of these types of incidents reoccurring.

Current Status: Completed

| Name | Tensile Structure | Shackle Failure | Warrantee Claim |

| Location | Melbourne , Victoria |

| Type | Investigation & Report |

| Client | Legal & Insurer |

Details :

Engaged by one of Australia’s leading insurance law litigation firms representing the insurer of a recently installed tensile fabric structure that had collapsed during a moderate wind event. Our brief was to investigate and write a detailed report into the failure including site inspections, review photograph evidence of the failure and interview contractors that removed the sail following the incident.

We found that the cause of the failure was due to the unwinding of a incorrectly installed shackle pin used to attach the sail to its perimeter support posts. This resulted in a corner point breaking free and causing the sail to tear in several sections.

The failure of the shackle pin was found to be an installation fault due to the failure to install a wire mouse through the shackle to prevent unwinding of the thread. The installation contractor denied liability, so the matter was then subject to legal proceedings which after some negotiation was settled in the claimants favour.

Current Status: Completed

| Name | Tensile Structure | PTFE & PVC Fabric Testing |

| Location | Australia , USA & Europe |

| Type | Investigation & Report |

| Client | Legal & Insurer |

Details :

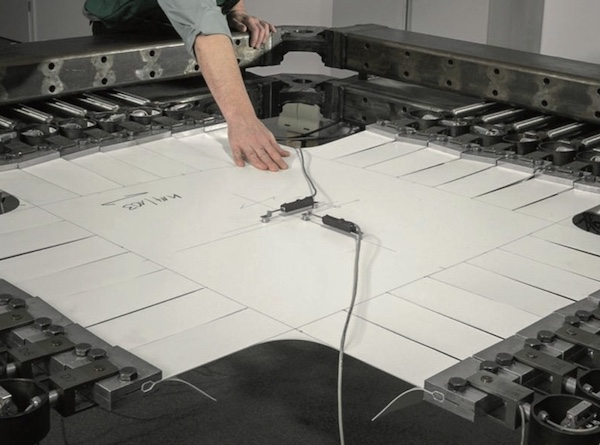

Working with testing labs in Europe and Australia Mainsailz undertakes a range of tensile fabric testing methods to check for surface flex cracking , loss of tensile strength and UV breakdown. By utilizing our custom designed fabric clamp plate system, we are able to remove testing samples from existing fabric structures without effecting the structural stability of the design and at the same time install a waterproof replacement section to the skin of the structure.

Current Status: Completed

| Name | School Tensile Structure Failure |

| Location | Queensland, Australia |

| Type | Design Failure |

| Client | Legal |

Details :

This matter involved the failure of a waterproof fabric structure, located on the rooftop of a school

science block. We were engaged by the lawyers representing site contractors to investigate the

cause of the failure and the history of the project.

We were informed that prior to the commencement of construction, the design engineer

advised the project architects that a 20-degree fall was required “to prevent ponding”. The

Architect agreed with this advice and issued for construction fabrication drawings for the sail

and posts manufacture.

Soon after completion the structure pondered with water and collapsed during a heavy rain

event. Measurements of posts heights and set out taken by a forensic engineer after the

collapse showed that the degree of fall was somewhere in the region of 9- 11%.

It was established beyond reasonable doubt that the failure of the structure was caused by the

project architect ignoring professional advice regarding degree of fall required on the

waterproof fabric.

Current Status: Completed